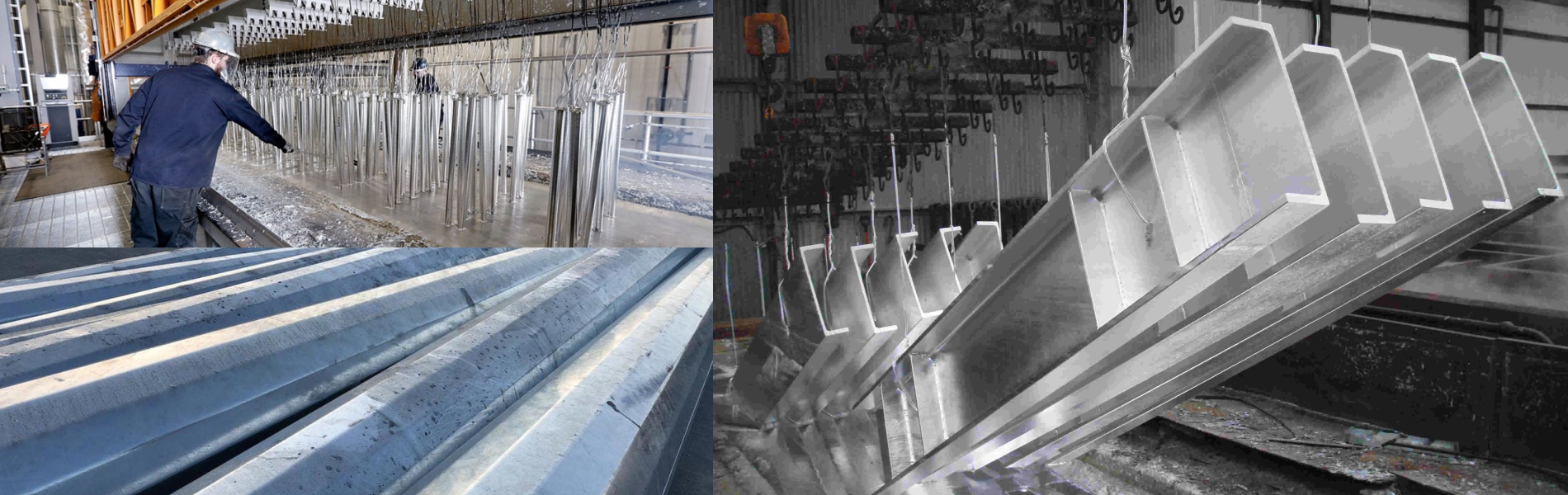

Hot Dip Galvanizing

At Steel Store, we offer comprehensive Hot Dip Galvanizing solutions for a wide range of fabricated products, including cable trays, cable ladders, gratings, foundation bolts, and more. With our advanced galvanizing process, we provide superior corrosion protection, ensuring that your fabricated metal components withstand the rigors of harsh environments and maintain their structural integrity for years to come.

Our Hot Dip Galvanizing Process:

- Surface Preparation: We begin by thoroughly cleaning and preparing the surface of your fabricated products to remove any contaminants, ensuring optimal adhesion of the zinc coating during the galvanizing process.

- Fluxing: The prepared metal components are then immersed in a flux solution to further cleanse the surface and facilitate the bonding of the zinc coating.

- Galvanizing: Next, the fabricated products are dipped into a bath of molten zinc at temperatures ranging from 815°F to 850°F (435°C to 455°C). This process forms a metallurgical bond between the zinc and the metal substrate, providing unparalleled corrosion protection.

- Quenching and Finishing: After galvanizing, the coated products undergo quenching to solidify the zinc coating and prevent excessive oxidation. They are then inspected, passivated for enhanced corrosion resistance, and dried before being ready for use or installation.

Benefits of Our Hot Dip Galvanizing Solutions:

- Exceptional Corrosion Protection: Our galvanizing process provides superior corrosion protection, extending the lifespan of your fabricated products in even the harshest environments.

- Enhanced Durability: The zinc coating enhances the durability and longevity of your fabricated components, reducing the need for frequent maintenance or replacements.

- Cost-Effective Solution: Hot Dip Galvanizing offers a cost-effective method of corrosion protection, resulting in long-term savings by minimizing maintenance costs and downtime.

- Versatility: Our galvanizing solutions are suitable for a variety of fabricated products, including cable trays, cable ladders, gratings, foundation bolts, and more, making them ideal for diverse applications across industries.

Applications: Our Hot Dip Galvanizing solutions are suitable for a wide range of fabricated products, including but not limited to:

- Cable trays and cable ladders

- Gratings and trench covers

- Foundation bolts and anchor rods

- Structural steel components

- Industrial machinery and equipment

- And more!

Contact Us: Protect your fabricated products with our premium Hot Dip Galvanizing solutions. Contact us today to discuss your galvanizing requirements, request a quote, or learn more about our capabilities. Let us help you ensure the longevity and performance of your fabricated metal components with our expert galvanizing services.